Image may be NSFW.

Clik here to view. Business Intelligence (BI) is a fascinating combination of words. Each time I hear about BI, I’m confused a bit. The formal definition of BI is very complex. Here is the extract from Wikipedia and, in my view, it is too long to be explained to a human. You can navigate to the following Wikipedia link to read more.

Business Intelligence (BI) is a fascinating combination of words. Each time I hear about BI, I’m confused a bit. The formal definition of BI is very complex. Here is the extract from Wikipedia and, in my view, it is too long to be explained to a human. You can navigate to the following Wikipedia link to read more.

Business intelligence (BI) mainly refers to computer-based techniques used in identifying, extracting,[clarification needed] and analyzing business data, such as sales revenue by products and/or departments, or by associated costs and incomes.[1]. BI technologies provide historical, current and predictive views of business operations. Common functions of business intelligence technologies are reporting, online analytical processing, analytics, data mining, process mining, complex event processing, business performance management, benchmarking, text mining and predictivepan> analytics. Business intelligence aims to support better business decision-making. Thus a BI system can be called a decision support system (DSS).[2]

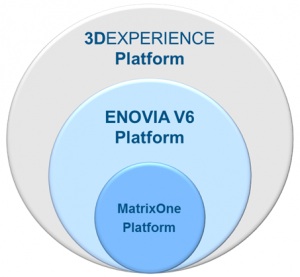

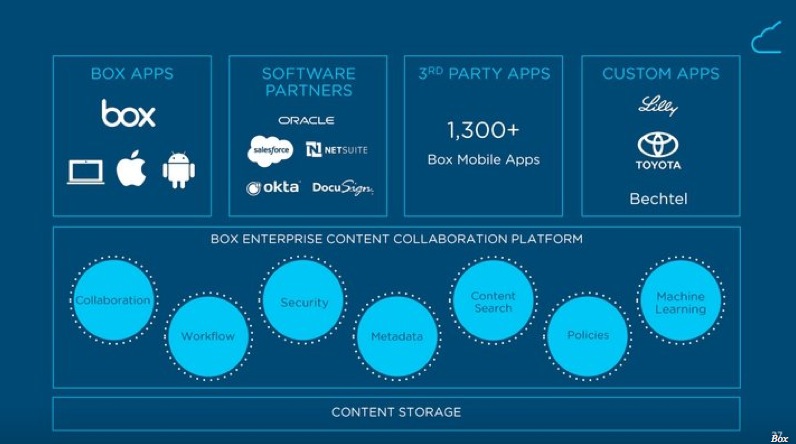

For many years, I thought about BI as a reporting mechanism or set of tools. The number of vendors in this space decreased significantly after mega acquisitions that were made in this space by Oracle (Hyperion), SAP (Business Objects) and IBM (Cognos). Few more acquisitions in this space were made, but today I don’t see a dominant pure-BI player that competes with large three I mentioned above.

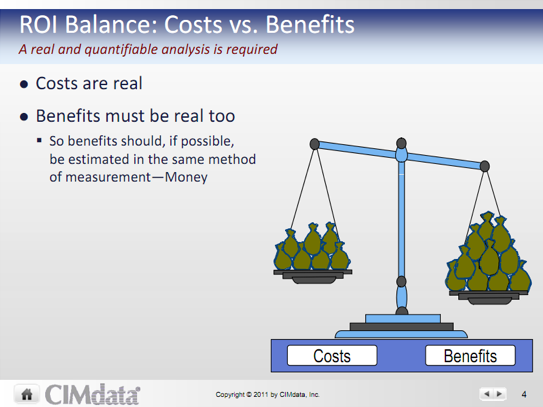

Is there a role BI can play in PLM? CIMdata recently published a white paper "The strategic value of Business Intelligence in PLM". The paper sponsored by eQ BI Technology – an interesting outfit playing with BI technologies in the domain of product development. The whitepaper is available for free and you can download it from CIMData website. Navigate to the following link (note- you have to be a registered user of CIMData. It is free, but I found CIMData website user experience a bit complicated). What I can learn from CIMData pages, in a nutshell, can be summarized as following.

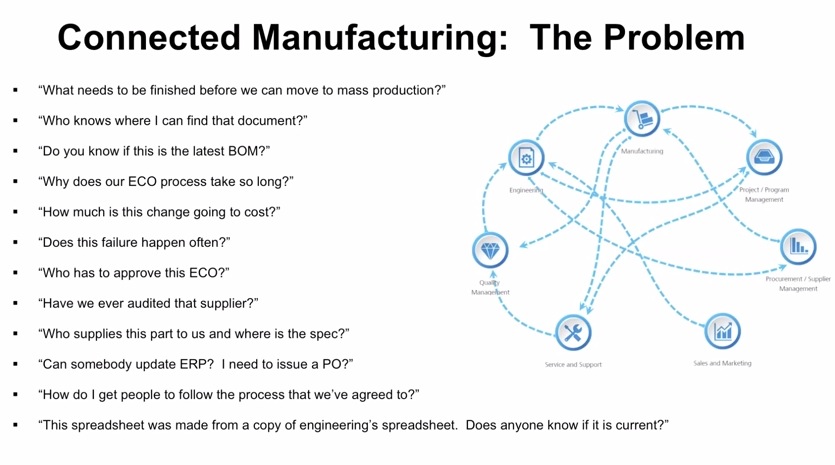

1. To analyze information in manufacturing company is important, and it is not a simple task.

2. Decision makers need to have various types of information reports

3. Many of the available solutions in this space are complicated and not easy to deploy and use.

4. The value of a potential solution that can bring a decision-oriented information can be significant.

Here is an interesting passage from CIMData paper:

Personnel at all levels need concise, timely information tailored to their task needs, regardless of whether they are a designer, a project management or a senior executive. To address the torrent of data that is being created by multiple business systems, companies are using business intelligence and analytics solutions that provide users the right information, in the context, for their needs. This is especially important for product development and PLM. BI solutions gather, aggregate, analyze and disseminate information with historical, current and predictive views of that information to facilitate decision making.

CIMData wasn’t the only analytic company in PLM space researching Business Intelligence topic. Jim Brown ofTechClarity discussed the value of BI in PLM in his whitepaper – Business Intelligence Extending PLM value. This paper was published back in 2009, but I found it quite relevant today. Jim is talking about multiple options of BI applications that can provide a return – connecting engineering and services, improving project timeline, identify cost saving opportunities and many others. Here is a passage from Jim’s conclusion about BI:

PLM implementations have matured to a scope and state that offer significant potential value from mining the underlying data. Accessing this information can help identify exceptions, manage and improve processes, and identify strategic trends that may uncover significant insight and value.

What is my conclusion? BI is clearly addressing the right problem. However, it seems to me, the approach of BI is a bit outdated. My hunch there is a segment of BI market that will pay big money to analyze their business data. The two companies CIMData brings in their whitepaper – Lockheed Martin and ATK Space are probably these types of companies. However, for many companies’ BI – means an expensive addition to existing ERP systems (result of Oracle, SAP and IBM acquisitions). If I will try to think about BI in simple language, I’d be still using word "reporting". eQ BI (company mentioned by CIMData) is providing reporting solution for TeamCenter. To extend reporting solutions of existing PLM tools can be a reasonable next step for BI in PLM. Just my thoughts…

Best, Oleg

Image may be NSFW.

Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.